A Laminar is used to control particulate contamination and is defined as air circulating at same velocity and in the same direction with no or minimal cross-over of air streams. If the air flow pattern becomes turbulent then there will be swirls and eddies that might lead to deposition of particles randomly on the surface and unpredictably. Laminar flow systems are required in the environments prone to contamination frequently as they sweep particles in a uniform direction from the clean area (filter face) to the exit which is present in the back or bottom of the hood. These systems are designed in such a way that the cleanest area will always be the upstream area closest to the filter face. All the work is done in this clean zone as it is made germ free and there is less possibility of creating turbulence.

Based on the clearance requirements, work surface design, process location and operator safety, the direction of the air flow is decided. In case of vertical laminar air flow, the air flows downward from a filter positioned above the work surface. In horizontal laminar air flow, the filter is placed behind the work zone.

Horizontal vs Vertical Laminar Air Flow System

Vertical Laminar hoods resemble the design of a small scale laminar flow cleanroom in which the filter is placed in the ceiling. The air is directed downwards, and all the particles are made to sweep out of the enclosure through the front access area. Majority of the dust and micro-contaminants are removed from the work surface. Hence vertical laminar air flow chambers are widely chosen.

Vertical Laminar Flow Diagram

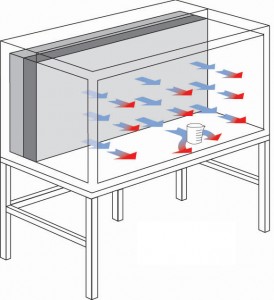

On the other hand, Horizontal Laminar hood requires more floor spacing with additional rear clearance to allow air to enter the system. Airtech provides both Horizontal and Vertical Laminar Air Flow Systems which provide effective sweeping action and maintaining required contamination free zone. Based on the applications, the type of laminar air flow cabinet must be selected. These laminar flow systems can also be used where the floor space is premium i.e. they can be easily detached and placed on the standard lab bench.

Horizontal Laminar Flow Diagram

………….> Contaminated Air

…………..> Filtered Air

To buy Horizontal Laminar Airflow from Antech visit https://www.firstsourcels.com/antech

We need to also keep in mind the risks to which an operator is prone. In case of horizontal laminar air flow, the air exists from the front opening. If there are any fumes or fine powders, then it might be blown on the operator’s face which might be risking his/her life. Hence in such situations, it is recommended to use Vertical Laminar Air Flow system.

Things to be considered for both Horizontal and Vertical Laminar Hoods:

- Any bio hazardous experiments should not be performed in both. A specially designed cabinets called BioSafety Cabinets of various classes must be used. Based on the toxicity of the contaminants, the levels of the BSC have been decided.

- Always run the laminar hood for 15 minutes prior to performance of actual operation. This removes the dirt particles clogged on the filter.

- Always keep the hood clean. They should be cleaned before and after operations. Any dirty operations like unpacking samples must be done away from the filter.

To compare different models of BioSafety Cabinets, Horizontal / Vertifical Laminar Airflow visit https://www.firstsourcels.com/sterilizing/cabinets

Pros and Cons of Vertical Laminar Flow Cabinets:

Pros:

- Requires less space

- Suits compounding sterile products

- More safe as the air doesn’t directly flow on to the person’s face.

- Access to filter is easy because it’s positioned on the top

- Less turbulence

- Minimal cross-contamination

Cons:

- Space is less so it might be congesting.

- There will air flow obstruction if items are placed one above the other.

Pros and Cons of Horizontal Air Flow Cabinets:

Pros:

- Reduced turbulence effect

- No sash and hence easy to work

- Less contamination of hands and gloves

Cons:

- Servicing of filter must be done regularly

- Fumes are blown towards operator’s face

Subscribe us on FirstSource Laboratory Solutions to receive the latest industry news, product info and technical resources of Biotech, Environment, Food and Beverages, Fluid Handling, Laboratory Research, Pharmaceutical etc.

FirstSource for your Cell Culture Lab

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop

FirstSource Laboratory Solutions Official Blog First Indian Scientific Online Shop